Foundry Tech: Grey Irons and SG Irons

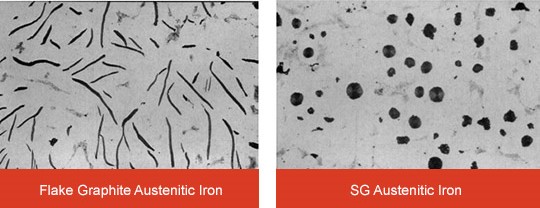

In the last two articles, we’ve looked at Grey Irons and SG Irons. Both have varying amounts of ferrite and pearlite to adjust the physical properties such as strength and hardness. There is another family of irons with a structure known as austenite. These Austenitic Irons are also commonly known as Ni-Resist. They’re available with either graphite flakes as in Grey Iron or with graphite nodules as in SG Iron.

These Irons are alloyed in various grades from 12 to 36% Nickel, which results in an austenitic matrix. Austenite is a relatively ductile crystalline structure that gives these irons some interesting properties.

Austenitic Irons can be used in salt solutions, seawater, mildly acidic or alkaline applications and oil field liquids. Their corrosion resistance is superior to Grey Iron or SG Iron. However, they are not stainless steels and do not behave as such. Corrosion is uniform rather than localised deterioration.

Wear resistance is another advantage, especially in metal-to-metal applications. Galling resistance is excellent. Another strength is resistance to corrosion-erosion in slurries and wet steam applications.

Finally, Flake Graphite Austenitic Irons can be used in temperatures up to 320°C and the SG versions up to 1050°C, as the oxide layer formed is very tenacious and stable.