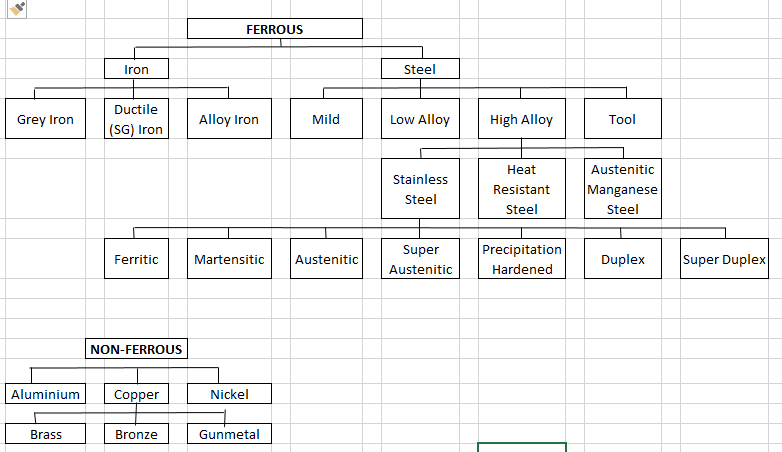

Foundry Tech: Metals & Alloys

Please enjoy this series of that explore the technical structures of metals & alloys that are used at White Industries.

Foundry Tech: Alloy White Irons

In this article, we’ll look at another member of the iron family – Alloy white irons (No, not named after White Industries.). White iron has a white appearance when fractured, just as grey iron has a grey fracture face. Alloy white irons differ from grey or SG iron; while they have similar carbon contents, the …

Foundry Tech: Aluminium

Up till now, we’ve explored ferrous alloys, those based on the element Iron (Fe). In this article, we start exploring non-ferrous alloys with this article devoted to Aluminium (or Aluminum), or what some people refer to as “alloy”. Aluminium is a lightweight metal, approximately one third the density of Iron. While these materials are not …

Foundry Tech: Austenitic Manganese Steel

Another highly alloyed steel family is Austenitic Manganese Steel (AMS). The original grade was invented by Sir Robert Hadfield in the 1880s, and the family is still referred to as Hadfield Steel. This family of steel contains anywhere from 11-25% Manganese, 0.6-1.5% Carbon and various combinations of Chromium (for improved abrasion resistance) and Molybdenum (for …

Foundry Tech: Brasses and Bronzes

In this newsletter, we are looking at Brasses and Bronzes. You’ll note that some brasses fall under bronzes, and vice versa. This is due to various naming conventions over the years. Brasses This is a broad term which is split into 4 subgroups, they are: Red and Leaded-Red Brasses, and Semi-Red and Leaded-Semi-Red Brasses are alloyed …

Foundry Tech: Copper-based alloys

In this edition, we’ll begin exploring copper-based alloys. They are a widely used family that has been around since around 3300 BC. The copper family falls under the following main groups, which are further split into subgroups as different alloying elements are added: Copper – greater than 99% Cupper (Cu) High Copper Alloys – greater than …

Foundry Tech: Fettling and Heat Treatment

In this edition, we look at Fettling and Heat Treatment. When a pattern is being prepared for moulding, extra features are added such as a runner bar and pouring cup, so the metal can enter and fill the mould cavity at the right speed (too slow and the metal will freeze, too fast and the …

Foundry Tech: Grey Irons and SG Irons

In the last two articles, we’ve looked at Grey Irons and SG Irons. Both have varying amounts of ferrite and pearlite to adjust the physical properties such as strength and hardness. There is another family of irons with a structure known as austenite. These Austenitic Irons are also commonly known as Ni-Resist. They’re available with …

Foundry Tech: Low Alloy Steel or LAS

In this article, we’ll look at the workhorse of industry, Low Alloy Steel or LAS. This family of steels has many different properties can be produced to meet different needs, such as strength, hardness, wear resistance etc. LAS is used in dragline rigging components, crusher components, heavy transport suspension parts and rail components, just to …

Foundry Tech: Materials Produced at White Industries

We offer a wide range of different materials at White Industries. Usually, our customers supply a drawing that specifies a material, and we produce to that specification. Sometimes a customer won’t know what material the casting should be made in, so we offer metallurgical advice based on the intended use. Some castings need a certain …

Foundry Tech: Nickels & Alloys

Welcome to the final article in the series of Material Reviews that has been running for the last couple of years. Nickel and its alloys, like the stainless steels, offer a wide range of corrosion and/or heat resistance. However, nickel can accommodate larger amounts of alloying elements; mainly chromium, molybdenum, copper, and tungsten in a …

Foundry Tech: Stainless Steel

Mild and low alloy steels continue to be the most widely used ferrous materials, due to their cost-effectiveness and high-performance properties. However, they do have a tendency to rust or corrode if left unprotected. This is due to the affinity of Iron (Fe) to readily oxidise with Oxygen in the air (O2), or in water (H20), …

Foundry Tech: Tool Steels

The last ferrous metal system that we are looking at in this series is Tool Steels. Tool Steels occupy a unique position in the ferrous family in that components made of Tool Steel are used to make other steel parts. Tool Steels can be used to make pressing dies, punches, shear blades, machining tools and …