Foundry Tech: Fettling and Heat Treatment

In this edition, we look at Fettling and Heat Treatment.

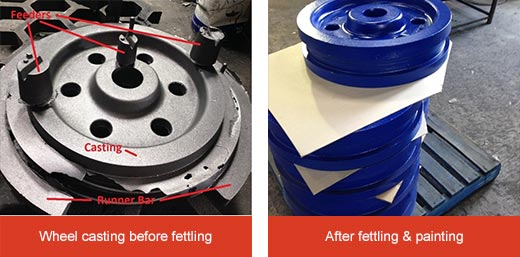

When a pattern is being prepared for moulding, extra features are added such as a runner bar and pouring cup, so the metal can enter and fill the mould cavity at the right speed (too slow and the metal will freeze, too fast and the metal will wash the moulding sand into the casting). Feeders or risers are also required to supply extra metal as the casting solidifies, otherwise shrinkage occurs inside the casting.

In the Fettling area, these extra features are removed with a pneumatic hammer, oxy acetylene cutting torch or grinders fitted with cutting disks, and the casting is ground with large grinders to smooth and blend the casting as required. The castings may then be painted to customer specification if required.

Metals such as cast iron, ductile iron, aluminium, brasses, bronzes and gunmetals can be used in their as-cast condition, i.e. they require no heat treatment to develop their properties.

Mild and Low Alloy Steels, on the other hand, require heat treatment to refine the grain structure and induce phase changes to develop the required characteristics, such as strength and hardness. In the case of Mild Steel, the castings are normalised (taken above their austenitising temperature) and air cooled. Low Alloy Steels require two further heat treatments; quenching from austenitising temperature to harden and tempering to remove quench stress and move the hardness and strength to the required range.

Austenitic and Duplex Stainless Steels require a solution treatment to eliminate sigma phase, which leads to stress corrosion cracking. This is done by heating to the austenitising temperature and water quenching.

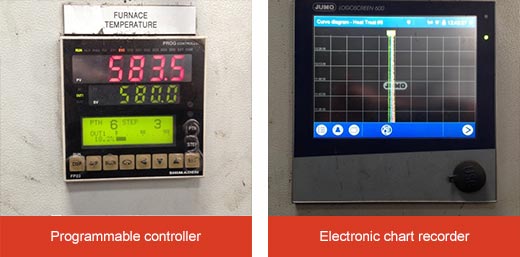

White Industries has six heat treatment ovens and a water quenching facility.

Each Oven has a programmable controller that controls the rate of heating and time at the required temperature. An electronic chart recorder records every heat treatment cycle for traceability.