Foundry Virtual Tour

Heat Treatment

White Industries operates six natural gas-fired heat treatment ovens and an agitated water quench facility to provide a wide range of thermal treatments such as annealing, stress relief, normalising, hardening and tempering.

Metals such as cast iron, ductile iron, aluminium, brasses, bronzes and gunmetals can be used in their as-cast condition, i.e. they require no heat treatment to develop their properties.

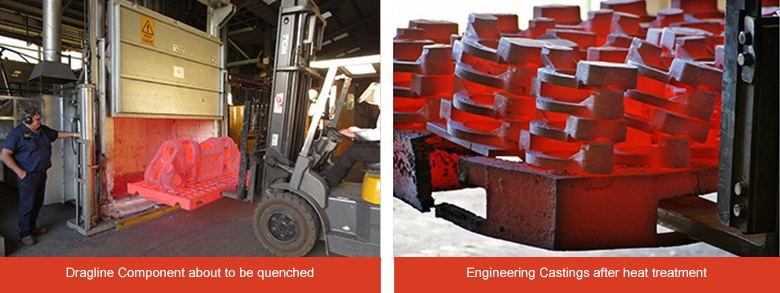

Mild and low alloy steels, on the other hand, require heat treatment to refine the grain structure and induce phase changes to develop the required characteristics, such as strength and hardness. In the case of mild steel, the castings are normalised (taken above their austenitizing temperature) and air cooled. Low alloy steels require two further heat treatments; quenching from austenitizing temperature to harden, and tempering to remove quench stress and move the hardness and strength to the required range.

Austenitic and duplex stainless steels require a solution treatment to eliminate sigma phase, which leads to stress corrosion cracking. This is done by heating to the austenitizing temperature and water quenching.

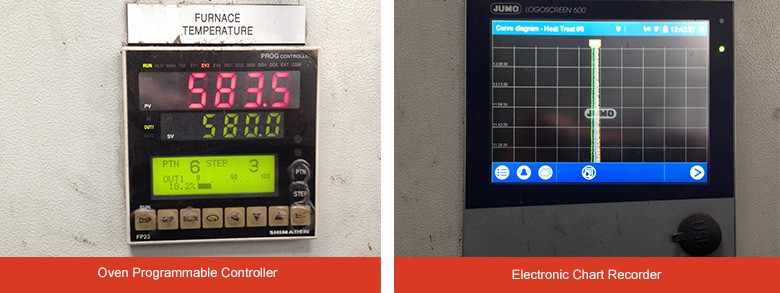

White Industries has six heat treatment ovens and a water quenching facility. Each oven has a programmable controller that regulates the rate of heating and time at the required temperature. An electronic chart recorder stores every heat treatment cycle for traceability.

All ovens are fitted with digital controllers that are programmed for precise heating rates and hold times. The ovens are equipped with digital recorders to maintain traceability of thermal cycles.

This enables White Industries to offer customers, steel and iron castings to exacting specifications, as well as a subcontracted heat treatment service.

The usable dimensions and operating temperatures are as follows:

| ven ID | Internal Height (mm) | Internal Width (mm) | Internal Diagonal (back wall to front door sill) (mm) | Internal Depth (mm) | Internal Diam (mm) | Temp Range (°C) | Comment |

|---|---|---|---|---|---|---|---|

| N°1 | 1520 | 2800 | 2130 | 1500 | – | 200-640 | |

| N°2 | 1550 | 2800 | 2150 | 1500 | – | 600-1100 | |

| N°3 | 1040 | 1460 | 1790 | 1460 | – | 600-1100 | |

| N°4 | 900 | – | – | – | 1980 | 600-1100 | |

| N°5 | 1550 | 1580 | 2610 | 2100 | – | 100-700 | |

| N°6 | 1580 | 1770 | 2370 | 4200 | – | 100-1100 | |

| N°7 | 1550 | 1580 | 2610 | 2100 | – | 150-300 | |

| Quench | 3500 Wide | 2500 Deep | – | 2500 Deep | – | – | Total quench water capacity with expansion tank 32,000 litres, with evaporative cooling tower. |

This is the final part of our Virtual Tour.

If you would like to enquire into how we can help you with your casting needs, contact us or call 1300 825 980.