Foundry Virtual Tour – Melting and Pouring

In this article, we look at the next step in the White Industries’ production process; melting and pouring. At the time of writing, White Industries produces 106 different alloys, consisting of various grades including:

| STEELS | IRONS | STAINLESS STEELS | NONFERROUS |

|---|---|---|---|

| Plain Carbon | Grey | Austenitic |

Aluminiums |

| Low Alloy | Ductile | Super Austenitic | Bronzes |

| High Alloy | Ni- Resist | Martensitic | Brasses |

| Ni-Hard | Ferritic | Gunmetals | |

| High Chrome | Duplex | ||

| Super Duplex |

Given the wide range of materials produced, White Industries employs strict controls to ensure scrap is identified and cross-contamination doesn’t occur. When a melt is programmed for production, a charge is calculated using known steel scrap, runners and risers from previous melts, and ferroalloys. All additions are weighed to ensure the melt analysis is in specification.

|

|

|

|

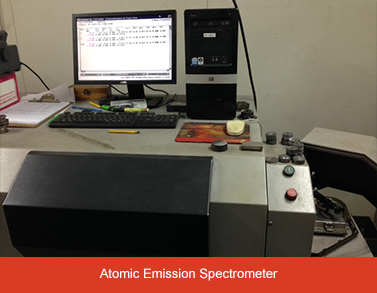

Melting is conducted in one of the five electric induction furnaces, with the scrap steel and returns added by electromagnet. The furnaces capacities are 1 x 150kg, 1 x 750kg, 2 x 2000kg and 1 x 3000kg. Once melting is complete, a sample is taken and analysed on one of the atomic emission spectrometers. A chemical analysis is compared against the specification and adjusted if necessary with ferroalloys.

|

|

|

|