Capital Investment

White Industries has always viewed the machine shop as an integral part of the business. In recent years, we have expanded the foundry as work load necessitated, so it makes sense that the same thing would have to happen with the machine shop. The purchase of two new Mazak lathes meant the decision was made to build a new machine shop (40m x 40m).

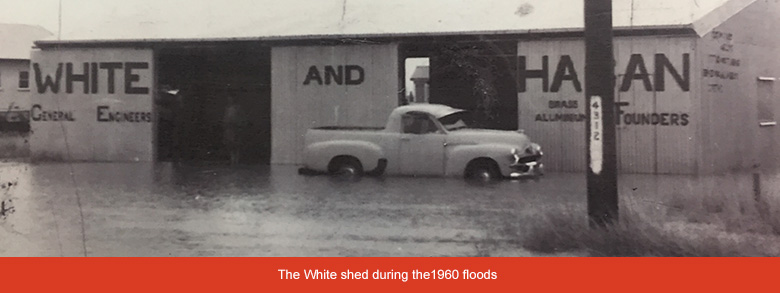

The issue we faced was how to erect the new shed with the least disruption to production. It was decided to build the new shed over the top of the existing shed, then pull the old shed down while the machines stayed fully operational. We also decided to raise the floor around 35 cms (14 inches) to bring the shed in line with the foundry floor height, giving us peace of mind that we should never have flood waters inside our sheds – unlike in White’s early years when the 1960 flood went into Dad’s shed not long after starting in business

We planned to only have one of our current nine lathes down at a time, and for no more than a week, giving it a birthday overhaul and relocating it in its new spot. So far five machines have been shifted with four to go when the old shed floor level is raised. The new lathes are scheduled to be deployed – one in September and the other in early November – upon the shed’s completion.

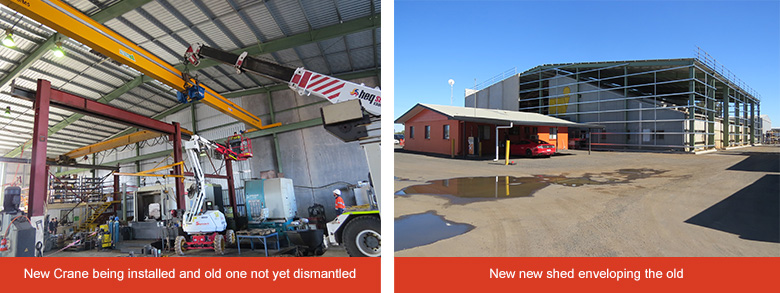

Two new overhead cranes, a 5t and a 10t, have been installed (replacing the old one) running side by side the full length of the shed. These were supplied by Eilbeck Cranes, one of our valued customers.