Foundry Tech: Low Alloy Steel or LAS

In this article, we’ll look at the workhorse of industry, Low Alloy Steel or LAS. This family of steels has many different properties can be produced to meet different needs, such as strength, hardness, wear resistance etc. LAS is used in dragline rigging components, crusher components, heavy transport suspension parts and rail components, just to name a few. Even within these groups of products, different components require different material properties. As an example, in dragline rigging, the locking pins need to be high hardness and strength, while the Y-Links need to be more ductile and hence softer with lower strength.

As the name suggests, Low Alloy Steels are steels that are intentionally alloyed with various combinations of Nickel, Chromium and Molybdenum up to a combined 8%. The Carbon content is the main element in achieving the enhanced properties, with Nickel, Chromium and Molybdenum increasing the hardenability. Other elements such as Vanadium and Boron can also be added to further enhance the required properties.

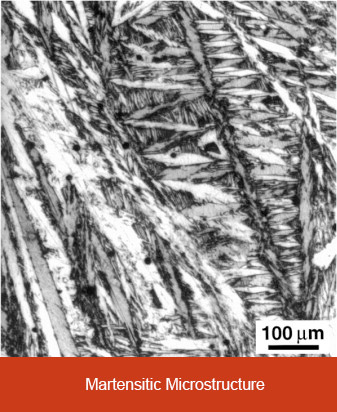

Heat treatment is also used to alter the properties of different parts from the same chemical specification. The hardening process consists of heating to the austenitizing temperature of greater than 900°C then quenched in either water or oil. The rapid cooling creates a crystalline form called martensite. Martensite is very hard and strong, but very brittle. To the right is a picture of the martensitic structure, with acicular or needle-like structures.

Heat treatment is also used to alter the properties of different parts from the same chemical specification. The hardening process consists of heating to the austenitizing temperature of greater than 900°C then quenched in either water or oil. The rapid cooling creates a crystalline form called martensite. Martensite is very hard and strong, but very brittle. To the right is a picture of the martensitic structure, with acicular or needle-like structures.

As-quenched martensite retains an enormous amount of stress that must be relieved, so all hardened steel in this state is tempered. If a low temperature temper is conducted, the stresses are reduced and very little of the hardness or strength is lost and the brittleness is reduced. The yield strength of such a steel may be up to 5 times that of a 250 plate steel. If a higher tempering temperature is used, hardness and strength is reduced and some ductility is restored, with yield strength up to 3 times that of 250 plate steel.

Low alloy steels are extremely versatile materials with the possibility of replacing plate steel fabrications with lighter, stronger castings, since the higher strength of the low alloy steel means less has to be used to achieve the same design function.